Our environmental interventions in Priolo

At the multi-company site, we are engaged in soil and groundwater remediation interventions on our areas and by mandate for the co-located companies.

The most sustainable remediation technologies at the service of the multi-company Priolo site

Priolo: key elements

Priolo at a glance

Priolo past and present

Site history

Start of the environmental process

In 2001, characterisation activities on the site began, and the following year Eni’s co-located companies began emergency safety measures and remediation designing.

Eni acquires the Montedison group’s assets

Following the Enimont operation, the Eni group entered the site through Enichem, which acquired the base and intermediate chemical plants as well as the refining facilities from Montedison.

The Priolo Gargallo industrial hub is created

Since its origin, the petrochemical hub has seen a significant expansion, marked by various corporate and operative directions, in the oil refining and derivatives processing sector.

Our activities in Priolo

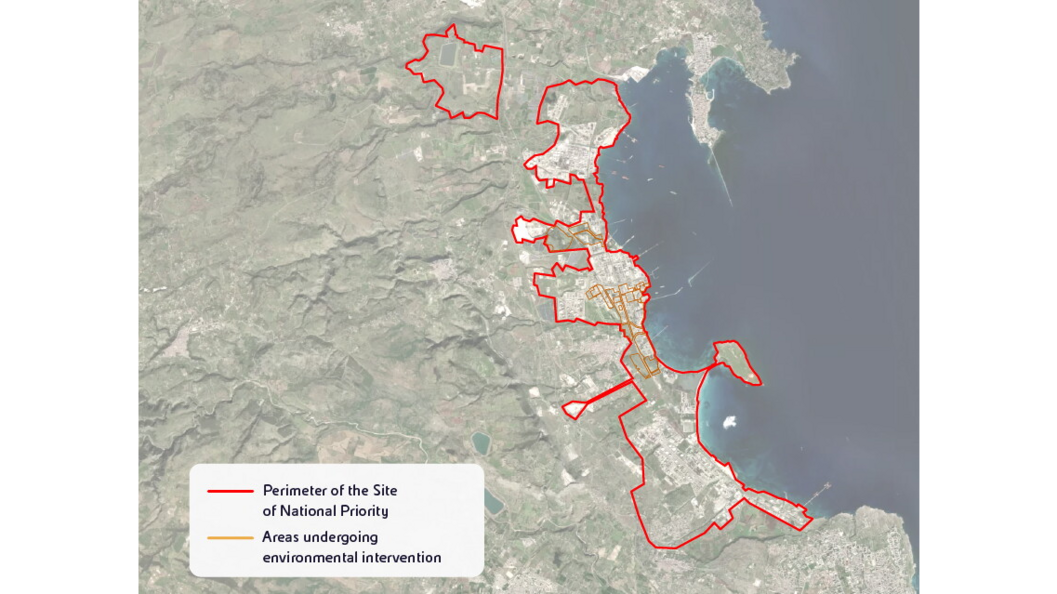

The Priolo Site of National Priority

Status of the environmental process

Starting from 2003, Eni's environmental company has submitted soil and groundwater remediation projects, some of which obtained authorisation by ministerial decree and are ongoing, while others are currently undergoing preliminary investigations.

Project approved

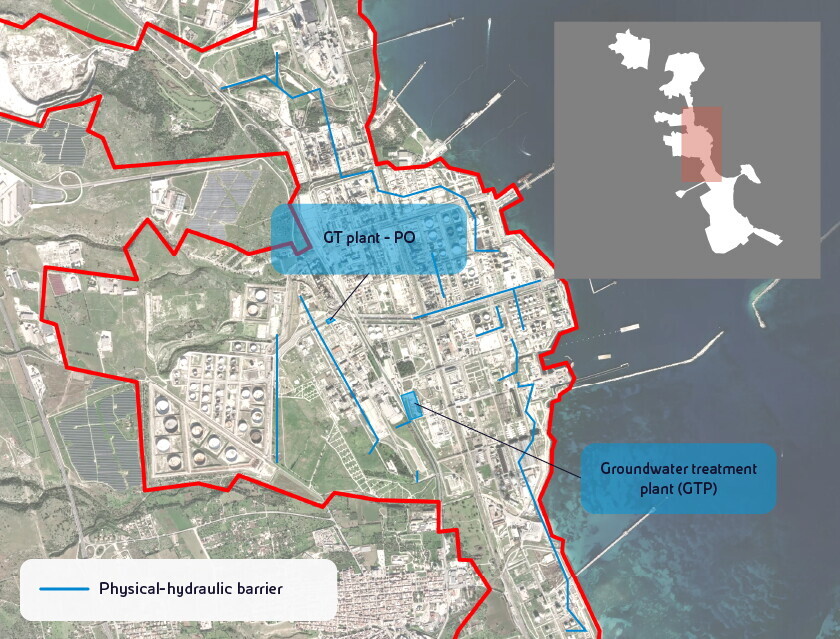

The definitive soil remediation project for the groundwater treatment plant (GTP) area was approved by interministerial decree in 2004 and amended in 2007 with authorisation for the construction of the water treatment plant.

The definitive groundwater remediation project for the entire multi-company site was authorised in 2004 by interministerial decree.

The project variant was approved in 2021.

The single multi-company groundwater monitoring protocol for the site was approved by the authorities in 2016.

Procedure undergoing preliminary investigation

Project approved. Variant undergoing preliminary investigation

Procedure undergoing preliminary investigation

Project approved

Procedure undergoing preliminary investigations

Procedure undergoing preliminary investigations

Project approved

Administrative process finalised

Sustainable remediation solutions

The areas south of the Vallone della Neve at Priolo’s site cover a total of approximately 196 hectares, of which around 26.8 are “non-compliant”. For soil remediation, following the top-soil removal intervention, we are applying the most advanced in-situ technologies aimed at treating contamination directly in the environmental matrix, including ISCO (In Situ Chemical Oxidation), TPE (Two Phase Extraction) with thermally assisted vapour extraction, Soil Flushing, and ECRT (Electro Chemical Remediation Technology). Following the interventions already completed, approximately 21.5 hectares can be released. In Area B3, we are also carrying out soil remediation using the Soil Vapour Extraction technology, while for the aquifer, the Permeable Reactive Barrier (PRB) technology is being applied on a pilot scale.