Our environmental interventions in Assemini

Environmental recovery, requalification and soil valorisation are the drivers of our strategy for the site.

Assemini, an example of remediation, productive requalification and valorisation

Assemini: key elements

Assemini at a glance

Assemini past and present

Site history

Transfer of the caustic soda assets

In 2021, Eni Rewind transferred to Società Chimica Assemini the caustic soda assets, as well as the water treatment and recovery plants in 2023.

Italkali takes over the the Conti Vecchi salt pans management

Italkali, as operator in the salt industry, acquired the shares of ILCV in 2022, taking over the management of the Conti Vecchi salt pans.

Production requalification of the salt and caustic soda cycle

The dichloroethane production plant was definitively halted and a requalification plan related to salt and caustic soda was launched through the controlled Ing. Luigi Conti Vecchi company.

Scaling down of the soda and dichloroethane production

Following the exit from the Italian market of Ineos (Vinyls Italia) which managed the CVM-PVC production plants, the Assemini site was downsized to include caustic soda and dichlorethane production.

The environmental recovery interventions begin

Enichem launched the first environmental interventions at the Assemini site, identified in 2001 as part of the Sulcis Iglesiente Guspinese Site of National Priority (SIN).

A plan for the industrial regeneration of the site

The industrial regeneration programme launched by Eni peaked in 1986 with the introduction in the caustic soda plant of a more sustainable membrane technology which replaced the mercury-based one.

The plant is conferred by law to Eni (through Enichem)

With the chemical industry crisis, the SIR Group's sites were transferred to Eni by Law No. 784/80. The assets included the Ing. Luigi Conti Vecchi company, owner of the salt pan concession.

Establishment of the Assemini site

The Assemini site is included in the Sardinian Revival Plan. Operations began with eight chemical companies, which later merged into Rumianca Sud and then into SIR.

Our activities in Assemini

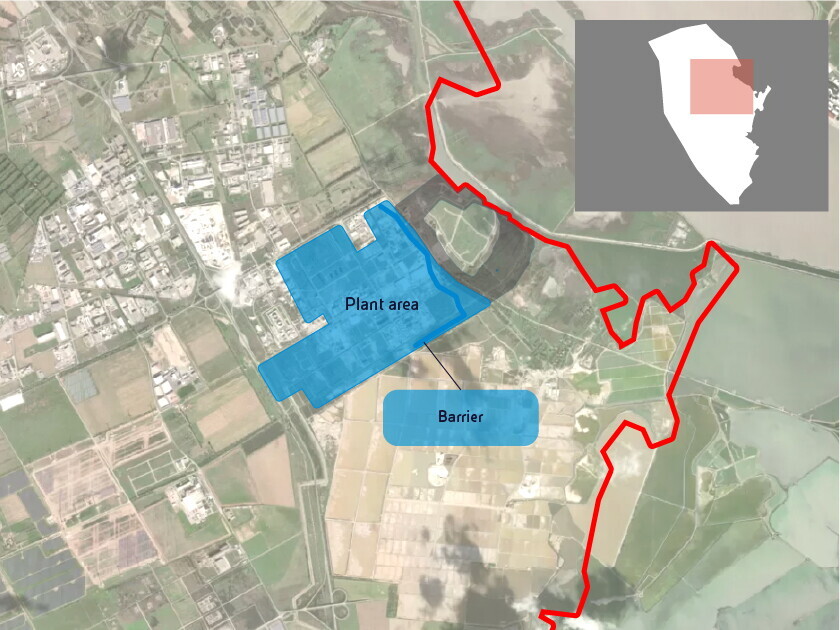

The Sulcis Iglesiente Guspinese Site of National Priority

Status of the environmental process

We are committed to the remediation of the internal and external areas of the plant in accordance with the ministerial decrees issued.

Project Approved

Project Approved

Project approved

Project approved

Project approved

Remediation project for the unsaturated soil matrix of Island 5 Area approved in 2019 by decree of the ministry of the Environment.

Project approved

Project approved

Sustainable and tailored remediation interventions

At the Assemini site, we carry out area remediation primarily by implementing various in-situ techniques, which are identified based on the type and distribution of contaminants:

- Enhanced Natural Attenuation (ENA) - technology selected for a total of approximately 55 ha distributed among the Plants and External Areas as well as the Coastal Deposit, which involves the anaerobic biodegradation of chlorinated hydrocarbons in the aquifer through the injection of easily biodegradable substrates.

- Air Sparging (AS) e Soil Vapor Extraction (SVE) - the intervention launched in 2024 includes the injection of air underneath the groundwater with the use of 161 dedicated wells, generating the stripping of volatile compounds and their transfer into the gaseous phase. This technology is combined with SVE, which is the recovery of the AS-generated vapours, extracted through a separate set of 125 windowed wells positioned in the unsaturated soil. Subsequently, the vapours are treated on active carbon filters. The AS/SVE plants’ arrangement in modules will enable their reuse in other sites at the end of the intervention.

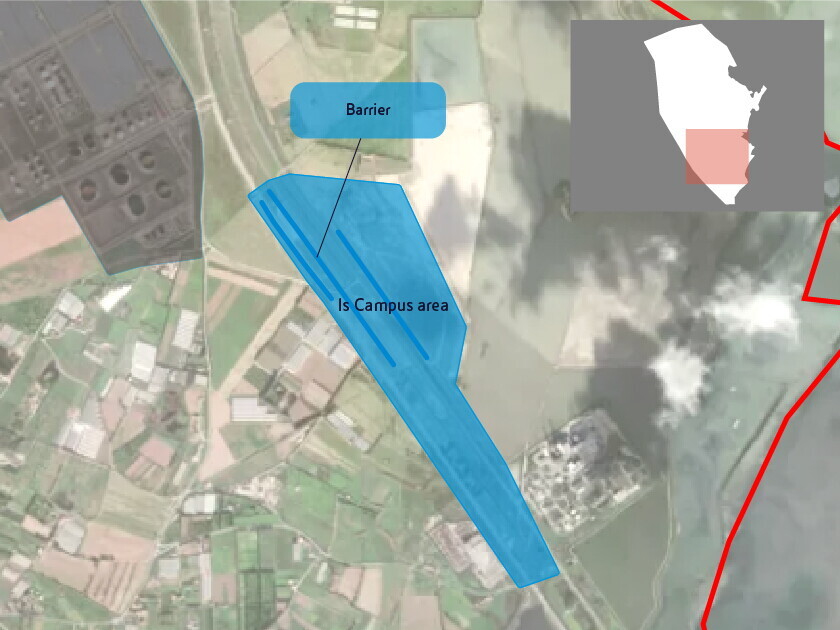

- Multi Phase Extraction (MPE) - the technology, applied on approximately 30 ha in the Is Campus Area, consists in the simultaneous extraction in liquid (submersible pump) and vapour (vacuum pump) phase, removing contamination from groundwater, as well as from the unsaturated and capillary zones. Here too, the plant can be moved and used in other sites at the end of the intervention.