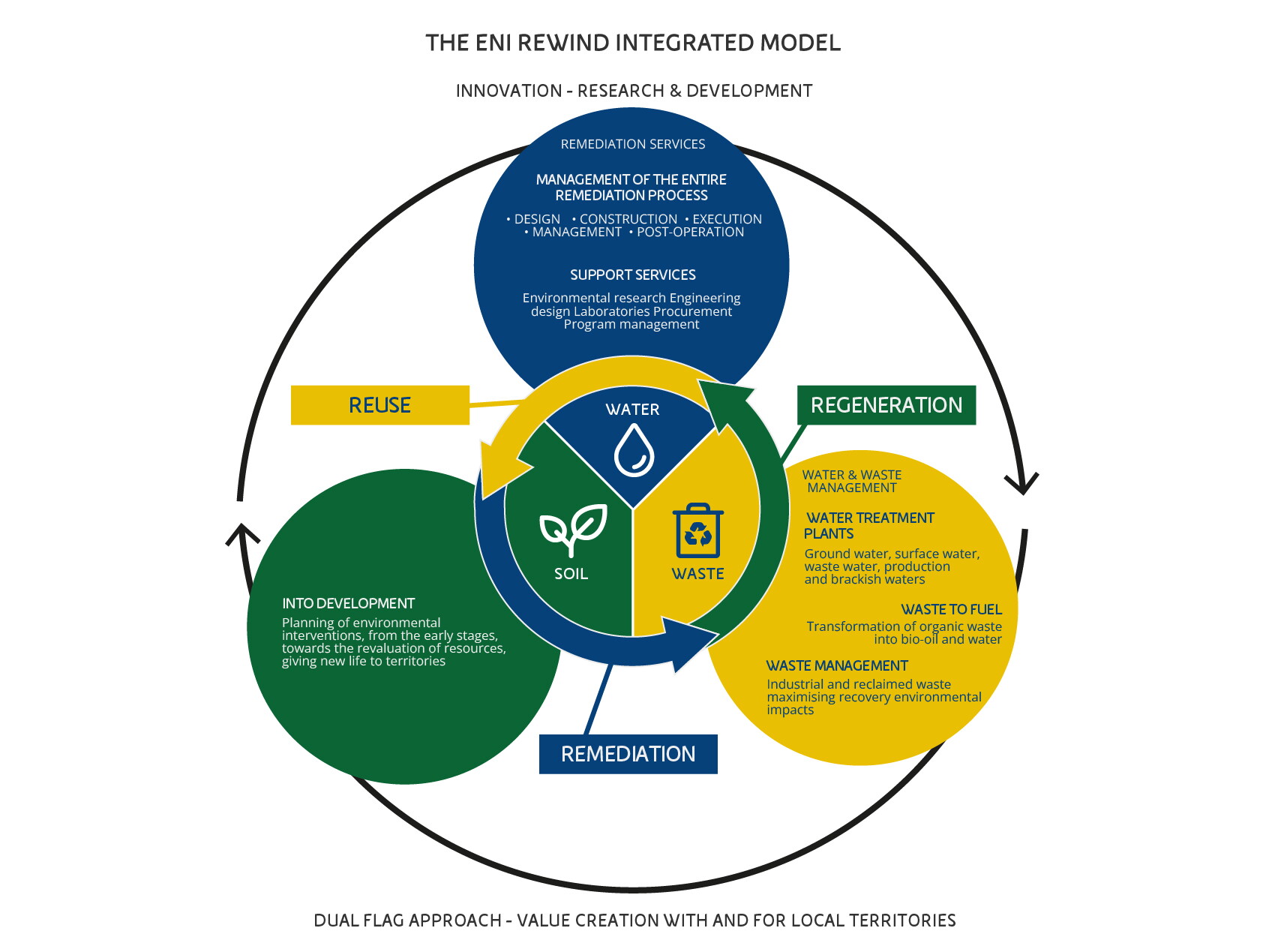

Our integrated model

We adopt an integrated operational model which enables the cross-management of the remediation process. This approach allows to plan the future reuse of the areas right from the earliest stages of intervention.

Integrated sustainability, from remediation to valorisation

Responsible commitment towards stakeholders

The power of sharing that creates value locally.

Our circular approach

Projects

We operate in over 150 sites and own approximately 3,700 hectares of land, mainly former industrial or brownfield sites in Italy.

Commitment for the environment and safety

Each of our people must be leaders in carrying out their activities in complete safety and with respect for the environment.

HSEQ culture is a corporate management policy based on four fundamental pillars:

- Health of the workers

- Safety of the operations

- Environment and sustainability

- Quality of products and services

As Eni's environmental company, we encourage an HSEQ culture, within a system of procedures and standards, that disseminates shared values, beliefs and behaviours able to influence the actions of employees. This is because we want a safe, healthy and sustainable work environment, which contributes to the growth of the company and its people. It requires everyone's commitment - from leaders to employees - to keep health, safety, environment and quality at the heart of company activities.

Awareness-raising initiatives on safety are aimed at both workers and suppliers, for the protection and benefit of activities carried out in complete safety.

Safety culture

Safety is not only “technical”, but above all behavioural. Eni actively promotes the Stop Work Authority, which is the right and duty to stop any activity in case of risk. Furthermore, it has launched training courses on safe behaviour, encouraging the conscious adoption of good practices through dedicated modules, workshops and simulations.

Fundamental safety rules

To guide safe behaviour, Eni Rewind leverages on two fundamental tools:

Principles and golden rules on safety: minimum requirements to be respected by employees and contractors, aimed at creating a culture of attention and responsibility.

Leadership and shared responsibility

A solid HSEQ culture also comes from credible leadership. Eni Rewind trains its managers to be active examples and daily promoters of safe, responsible and sustainable behaviour. Safety is a shared responsibility, in which every role has a concrete impact.

Learning from mistakes: valuable lessons

Every event, even a missed one, is an opportunity to improve. Eni Rewind systematically collects and disseminates, within various initiatives, the so-called lessons learned (HSE day, HSE take away, to name a few), facilitating the transfer of knowledge and the prevention of future incidents. This method is part of a practice of prevention and risk mitigation for the health and safety of workers and suppliers, strengthening continuous learning and organisational resilience. The goal is to eliminate the occurrence of accidents.

Training pills on SGI HSEQ

Training, information and awareness-raising courses on the requirements of health and safety, quality and environment standards for all Eni Rewind people.

Safety and environment pact

is an agreement between Eni Rewind and its contractors to adopt and use shared tools with the aim of carrying out contract work without injuries or significant accidents. The pact provides for the systematic detection of near-misses and sub-standard conditions with the aim of encouraging preventive actions and promoting continuous improvement of the culture of safety and management of environmental aspects by contractors.

The evolving Construction Site

“Evolving Construction Site” is an initiative aimed at contractors who operate on our sites characterised by increasing complexity. The goal is to ensure an increasingly safe and efficient construction site, acting on multiple fronts:

• consistently reduce the number of injuries and accidents

• reinforce environmental protection

• support daily decision-making processes with targeted monitoring

• increase awareness of all operators on the construction site

• consolidate risk containment barriers

• optimise the management of extraordinary emergencies

• raise staff awareness of weak signals, unsafe conditions and unsafe acts related to the environment and safety.

Documents

Documents

Management system

Our certifications guarantee quality, safety, environmental protection and regulatory compliance.

Our suppliers

The supplier qualification process is used to verify, assess and monitor the technical, organisational, ethical and financial capabilities of a potential supplier, ensuring compliance with HSEQ requirements in accordance with defined standards.

This activity is carried out by a multidisciplinary Eni team specialised in HSEQ issues that assesses the supplier by analysing documents and, if necessary, verifying skills in the field.

Using the supplier feedback process, we monitor their performance over time, technically, qualitatively and in terms of HSE, highlighting potential hazards and directing any mitigation actions. This allows us to confirm and review the assessment made at the qualification stage, as well as to make a selection based on their performance comprehensive of HSE aspects.